|

|

|

|

Bean

PWMMC

|

Pulse width modulation for motor control

Application Notes, Tips and Tricks for the bean. Hints for code optimization.

|

Application Notes:

Align

The Align selects either Center-Aligned or Edge-Aligned PWMMC generator outputs.

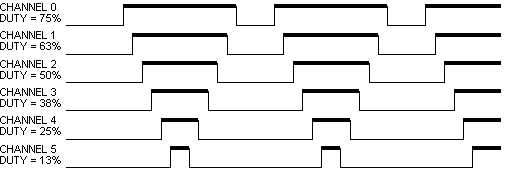

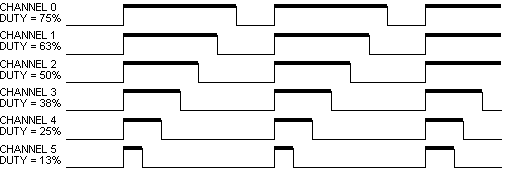

The center-aligned mode is shown on Figure 1. and

the edge-aligned mode is shown on Figure 2..

Period in the center-aligned mode is two times longer then in the

edge-aligned mode.

Figure 1. PWMMC Center-Aligned Mode

Figure 1. PWMMC Center-Aligned Mode

Figure 2. PWMMC Edge-Aligned Mode

Figure 2. PWMMC Edge-Aligned Mode

Mode

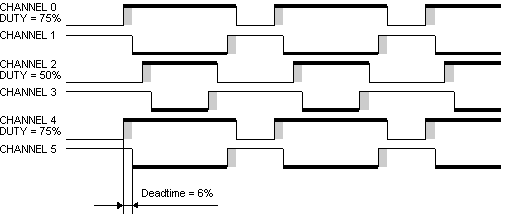

The Mode selects either Complementary Channel Operation (see Figure 3.)

or Independent Channel Operation (see Figure 1.) PWMMC generator outputs.

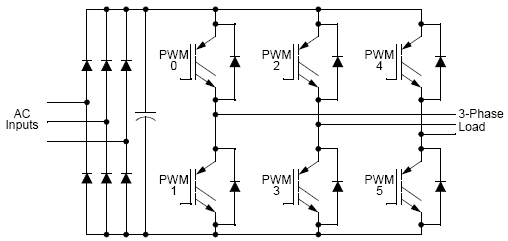

The complementary chanel operation drives top and bottom transistors in an inverter circuit, such as the one in

Figure 4..

Figure 3. Complementary Channel Operation

Figure 3. Complementary Channel Operation

Figure 4. Typical 3-Phase Inverter

Figure 4. Typical 3-Phase Inverter

Output Pads

The PWMMC output Pads can be enabled or disabled by property Output Pads.

The power-up default has the pads disabled. This settings does not affect the functionality of the

PWMMC, so the PWMMC module can be energized with the output pads disabled. The Output Pads can be

changed by the OutputPadEnable() and OutputPadDisable() methods. When the Output Pads

are disabled the PWMMC pins are set to the tri-stated.

Frequency / Output Frequency

The Frequency of the PWMMC output is set by this property. The right output frequency is shown in

Output Frequency.

Frequency in the center-aligned mode is half then in the

edge-aligned mode (see Figure 5.).

Figure 5. Frequency in Center-aligned/Edge-aligned mode

Figure 5. Frequency in Center-aligned/Edge-aligned mode

The PWMMC output frequency can be set by the SetPeriod() or SetPrescaller() methods.

Both methods is low-level methods and write the value of the parameter into register of the CPU.

The Value for setting Frequency property can be shown by the Peripheral Initialization Inspector

(see Figure 6.).

Figure 6. Peripheral Initialization Inspector

Figure 6. Peripheral Initialization Inspector

Dead-time

While in the Complementary mode, each PWM pair can be used to drive top/bottom

transistors, illustrated in Figure 4..

Ideally, the PWM pairs are an inversion of each other. When the top PWM channel

is active, the bottom PWM channel is inactive and vice versa.

To avoid short circuiting between top and bottom transistor, there must be no overlap of

conducting intervals between top and bottom transistor. But the transistorís characteristics

make its switching-off time longer than switching-on time. To avoid the conducting

overlap of top and bottom transistors, dead-time needs to be inserted in the switching

period.

Dead-time generators automatically insert software-selectable activation delays into each

pair of PWM outputs. The Pulse Module Dead-time (PMDEADTM) register specifies the

number of PWM clock cycles to use for dead-time delay. Every time the PWM generator

output changes state, dead-time is inserted. Dead-time forces both PWM outputs in the pair

to the inactive state. The dead-time is shown in Figure 3..

Duty

This property set the pulse width. In the real-time the Duty is set by SetDuty(), SetDutyPercent(),

SetRatio15() and SetRatio16() methods. The SetDuty() method is low-level method and

set the registers of the PWMMC. The Value of SetDuty() method parameter is availabled by

the Peripheral Initialization Inspector (see Figure 6.).

The Value of duty is shown in Figure 1.,

Figure 2., Figure 3.

by the thick line.

Reload / Half Cycle Reload

This property selects the PWMMC load frequency according Table 1.. Half Cycle Reload property

enables half cycle reloads only in Center-Aligned mode. Half Cycle Reload has no effect on Edge-Aligned mode.

Table 1. PWMMC Reload Frequency

| Value |

PWMMC Reload Frequency |

Value |

PWMMC Reload Frequency |

| 0 |

Every PWMMC Opportunity |

8 |

Every 9 PWMMC Opportunity |

| 1 |

Every 2 PWMMC Opportunity |

9 |

Every 10 PWMMC Opportunity |

| 2 |

Every 3 PWMMC Opportunity |

10 |

Every 11 PWMMC Opportunity |

| 3 |

Every 4 PWMMC Opportunity |

11 |

Every 12 PWMMC Opportunity |

| 4 |

Every 5 PWMMC Opportunity |

12 |

Every 13 PWMMC Opportunity |

| 5 |

Every 6 PWMMC Opportunity |

13 |

Every 14 PWMMC Opportunity |

| 6 |

Every 7 PWMMC Opportunity |

14 |

Every 15 PWMMC Opportunity |

| 7 |

Every 8 PWMMC Opportunity |

15 |

Every 16 PWMMC Opportunity |

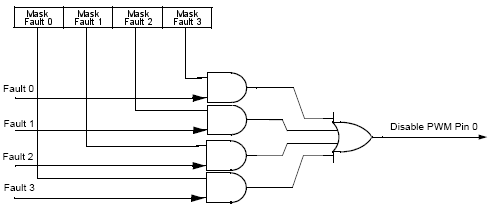

Mask fault x

Fault protection can disable any combination of PWMMC pins. Faults are generated

by a Logic 1 on any of the FAULT pins. Each FAULT pin can be mapped arbitrarily

to any of the PWMMC. When fault protection hardware disables PWMMC pins, the PWMMC generator

continues to run, only the output pins are deactivated. The fault decoder disables PWMMC

pins selected by the fault logic and the disable masking property. Please see

Figure 7..

Figure 7. Fault Decoder for PWMMC Channel 0

Figure 7. Fault Decoder for PWMMC Channel 0

Fault Clearing Mode

This property selects automatic or manual clearing of FAULTx pin faults.

When the Clearing mode is set to manual, the fault flag must be clear by the

ClearFaultFlag() method.

|

|

|

Processor ExpertTM and Embedded BeansTM are registered trademarks of UNIS, Ltd.

©1997-2005, UNIS, Ltd.

|

|

|